Continuous quenching furnace

Features:

Application: Hardening & Quenching

Material Heated:45#,40Cr,42CrMo,65Mn

Bar Diameter Allow: Φ20-110mm

Pipe Diameter Allow: Φ60-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

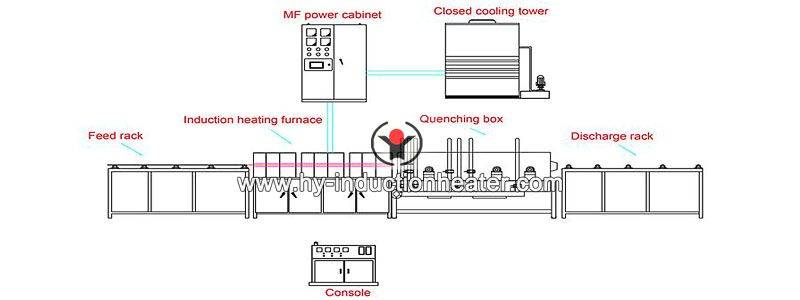

Product Name: Continuous quenching furnace

Product: Austenitizing+water quenching

Suitable for:Long bar, pipe, plate etc.

Advantage:No deformation, high efficiency

Typical Application:

With energy saving power supply and reliable control system, Forever Continuous quenching furnace is used for steel round bars hardening, surface hardening, through hardening.

Full automatic Continuous quenching furnace with PLC feeder and cooling device for hardening rods,bars and slab etc.

Induction hardening is a form of heat treatment in which a metal part is heated by induction heating and then quenched. The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction hardening is used to selectively harden areas of a part or assembly without affecting the properties of the part as a whole.

Features for Continuous quenching furnace

- Okay for small &big production capacity as threaded rod heated continuous one by one, and also the machine can start &stop work by only press a bottom

- The quality of finished product highly improved as single pieces continuous faster heating to avoid seriously oxidation & decarbonization (carbon lost along with heating)

- Power and water can support the running of whole system , no pollution, good for environment

- Hardening, tempering, surface finishing (to avoid oxidation) can be finished in one production line

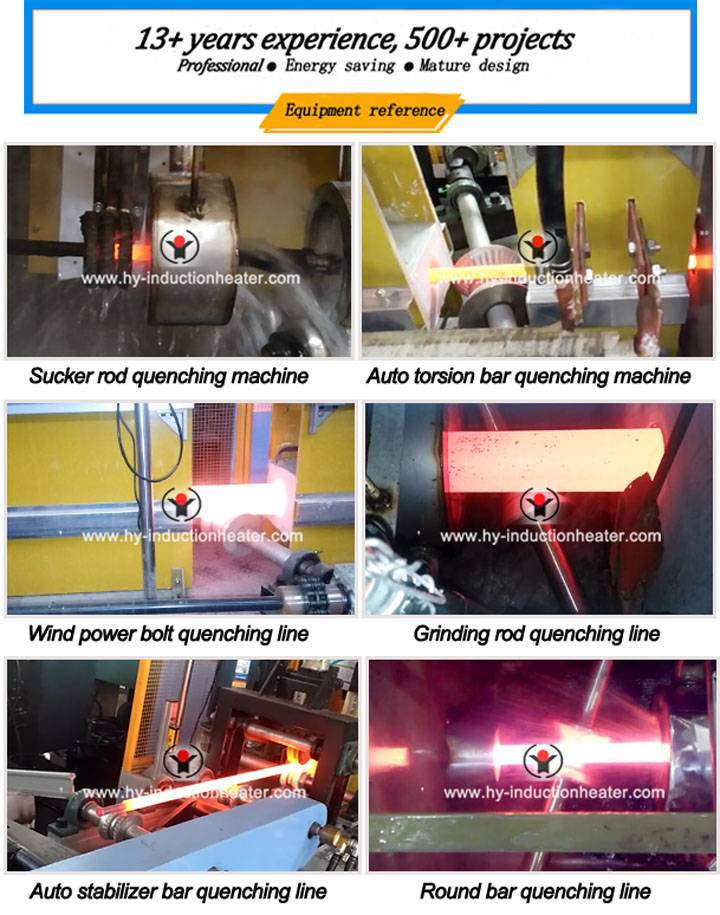

Applications for Continuous quenching furnace

- Sucker rod horizontal induction hardening machine see video

- Drill pipe,drill rod induction hardening see video

- Long bar induction hardening see video

- Long shaft induction hardening

- Slab induction hardening see video

- Anchor bolt induction hardening see video

Successful cases

| Diameter | Automatic Control | Power Design |

| Ø18-Ø28 mm(Steel bar) | PLC Control | IGBT200KW Quenching |

| Ø30-Ø70mm(Steel bar) | PLC Control | KGPS350KW Quenching |

| Ø80-Ø110(Steel bar) | PLC Control | KGPS450KW Quenching |

| Ø16-Ø32 mm(Sucker rod) | PLC Control | IGBT200KW Quenching |

| Shaft diameter | Shaft length | Heating Temp. | Quenching depth | Production capacity |

| Ø16 | 4m | 900℃ | 1.1~2.3mm | 120 PCS/H |

| Ø25 | 4m | 900℃ | 1.1~2.3mm | 60 PCS/H |

As our induction heater is all customized, the above parameters are only for your reference.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.